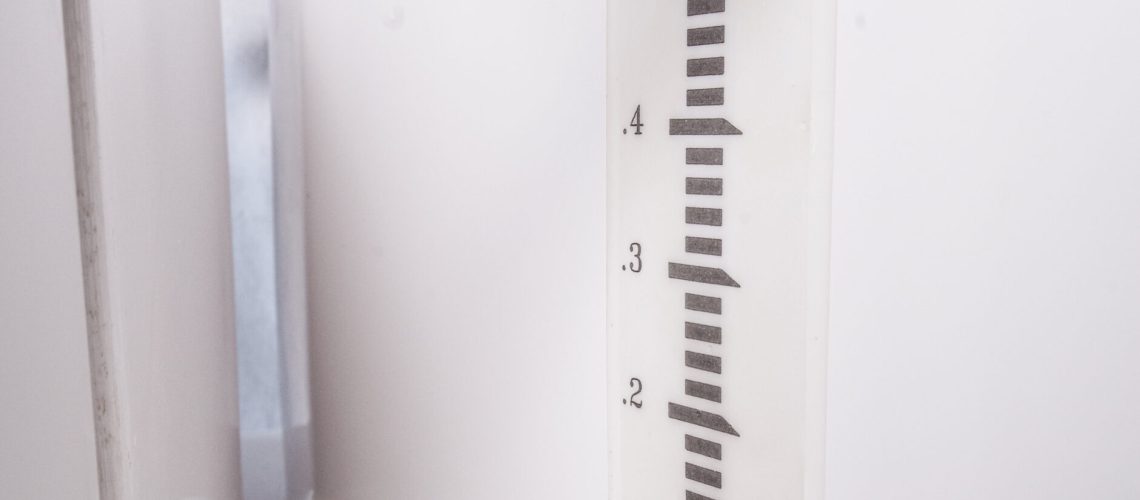

One of the most popular ways to take readings from a flume is to utilize a staff gauge. While reading these gauges may seem easy at a glance, there are actually a few ways it can go wrong without you even realizing it. To make sure you’re always taking the accurate measurements you need, be sure to abide by the top tips for reading staff gauges.

Understand the Markings

Not all staff gauges are marked the same way. Just because you’ve understood how one staff gauge works doesn’t mean you can automatically apply the same to a different staff gauge. For example, one staff gauge may denote markings for every tenth of a foot while another may only show markings for every fifth of a foot. If you’re dealing with a metric staff gauge, however, it’s almost always marked with bars at every 10 centimeters.

Consider Verticality

When using popular flume designs like the Parshall or the Cutthroat, you can simply apply a staff gauge on the vertical wall and read the surface level accordingly. Things get a bit more complicated, however, when the side wall of the flume isn’t perfectly vertical like when you’re using a Palmer-Bowlus or Trapezoidal flume.

When applying a staff gauge to a flume that doesn’t have vertical walls, you’ll need to either use a gauge that’s graduated, or you must implement a calibration adjustment. Palmer-Bowlus flumes are especially difficult, however, as the wall itself is curved. At least with Trapezoidal flumes, the angled wall is a straight line. When dealing with a curved wall, calibration isn’t an option. Instead, you’ll need to utilize a pre-calibrated staff gauge.

Pre-Calibrated Gauges

The easiest way to account for angled or curved walls is to get a pre-calibrated gauge. While technically unnecessary for flumes with angled straight walls, a pre-calibrated gauge allows you to treat them like a normal gauge on a vertical wall. The marking at the surface level’s point will tell you the vertical height of the flow even accounting for the distortion. Keep in mind, however, that these gauges must be applied precisely in the right spot in order to offer accurate readings. Fortunately, they’re just as easy to apply as their vertical counterparts.

If you opt for a higher quality flume, you may be able to get the staff gauge molded into the wall itself. This is the best way to ensure that it’s applied properly, especially in comparison to adhesive staff gauges, which are often applied by hand. These molded staff gauges become part of the flume’s sidewall, so they don’t alter the interior dimensions of the flume necessary for proper flow measurement.

Staff Gauges From Tracom

With these tips for reading staff gauges in mind, you’ll have everything you need to take accurate measurements you can count on with the proper equipment. If you’re looking for quality staff gauges, Tracom has got you covered offering numerous types and styles. Contact us today, and our team can work with you to find the best staff gauge or craft an entire flume with one built in.