When you’re implementing a flume into your flow channel, there’s a lot that can go wrong throughout the process. If you want accurate flow rate measurements, your flume installation needs to be spot on. Otherwise, you’re going to have to deal with adjustments and, potentially, restarting the entire installation process. The only thing you should be doing twice is measuring. Here are some helpful tips for proper flume installation.

Have a Smooth and Directed Transition

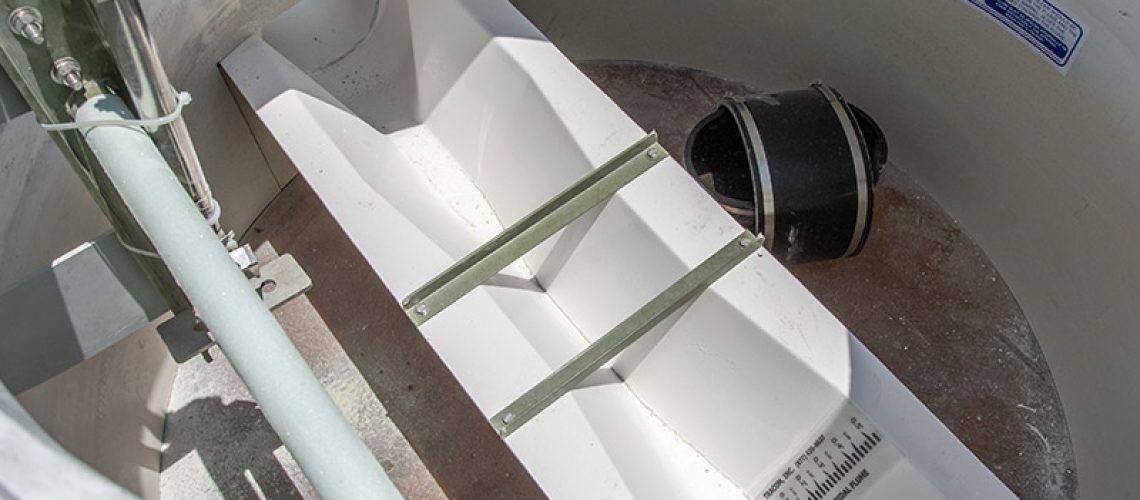

One of the most important aspects of any flume is a standard and uniform velocity profile for the flow on approach. Quite a few different factors can get in the way of this, such as hydraulic jump or sudden falls in which the flow drops with splashes that could send it in different directions. When you smooth out the flow using radius wing walls, you can gradually transition the flow into the flume, ensuring a good velocity profile that reaches criticality when it needs to.

To maintain the appropriate velocity profile, the direction of the flow also has to be controlled. It needs to enter the flow straight-on rather than at an angle. Additionally, no parts of the flow can go past the flume. The entire flow needs to pass through it. Wing walls that guide the flow into the narrower flume space can help ensure that nothing gets past the flume.

Ensure That the Flume Is Leveled

Among the most common installation errors for flumes, not ensuring that the flume is leveled is likely the most prevalent. While some flume designs, like the Parshall and cutthroat, can account for not being level with equation alterations, most flume designs cannot. This means that being level is among the most important aspects of the installation process. Plus, even among Parshall and cutthroat flumes, the alterations for not being level aren’t always possible depending on the degree of error.

While it can take some time, depending on the size of your flume, to make sure that the flume is flat, it’s essential that you ensure that it’s completely level from front to back upon installation. Additionally, you’ll want to make sure it’s also level from side to side. The entire flume must be flat in order to function properly and make sure that the equations and measurements produce results that accurately reflect the actual flow rate.

Get the Proper Size

Flumes come in many different shapes and sizes, but the larger the flume is, the more costly it is. Because of this, people often tend to opt for the smallest size they think they can get away with to save on cost. This can be a mistake if you don’t know exactly what you’re measuring with. After all, your flow may not always be consistent, but your flume will have to handle all conditions.

While it’s impossible to plan for every possible outcome, it’s critical that you don’t undersize your flume. A good rule of thumb is to size your flume in relation to your maximum anticipated flow rate rather than the typical flow rate. Leave some margin for error as well, just in case. Spending a bit more for a reliable flume is better than saving now but having to pay for a new one later.

Flumes From Tracom

With these tips for proper flume installation, it’s time to get a fiberglass flume for yourself. That’s where Tracom can help. Contact us today to get a flume of your own with help from our expert team!