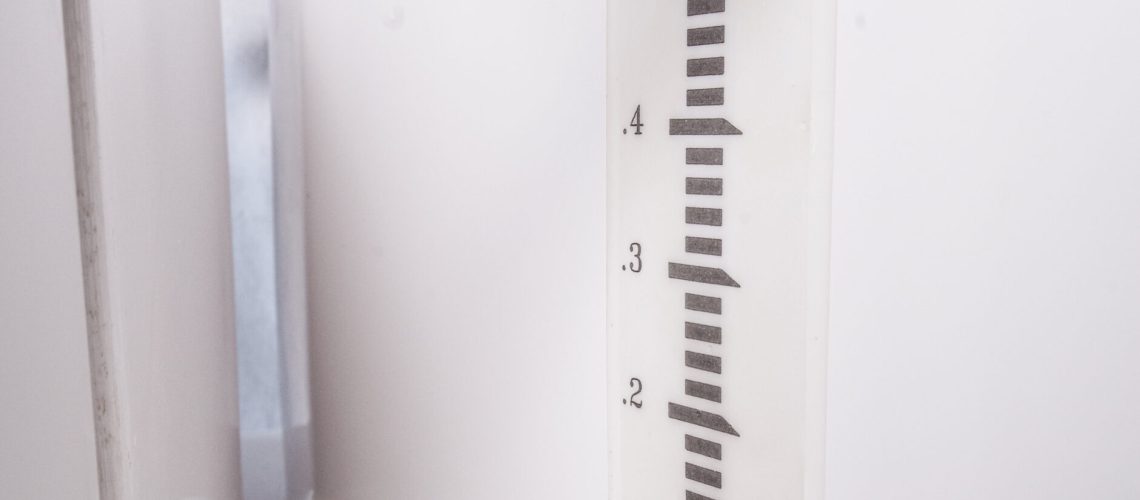

Staff gauges are among the most popular ways to take measurements in flumes and weirs because they’re not only easy to read, but relatively affordable as well. That convenience can come at a cost, however, if you happen to make any of the errors commonly associated with reading these gauges. Learn about the common problems with staff gauges, and discover how you can avoid them.

Too Far Away

When you get a staff gauge with clearly marked numbers and lines, you may think that you’ll have no problem reading it, but that’s not necessarily the case. The readability distance is dependent on the size of the staff gauge, so you’ll need to consider how far away you’ll be when reading it before you finalize which one you’re going to install.

When you’re trying to find the right size, it’s important to get an idea of how far away you’ll be when taking measurements. If your numeral height is about an inch, for example, you should be able to read that from about 25 feet away. If your numeral height is 5/16 of an inch, your viewing distance is just 7 feet. On the other end of the spectrum, a numeral height of 9 inches should offer a viewing distance of 300 feet. A good quick way to help readability is to use contrasting colors like dark lines on a light background.

Bad Angle

Reading a staff gauge seems easy enough, but when most people imagine it, they picture themselves looking at it straight on. Unfortunately, that particular angle isn’t always an option in some applications where the viewer may find themselves significantly above the gauge with no way to get lower. When the angle is off like that, accounting for turbulence and even getting a general reading can be tough and increase the risk of faulty measurements.

Too Much Turbulence

Even if you have a good angle on an easily readable gauge, turbulence can still throw off your measurements. It’s difficult to tell what the actual surface level is when waves can make it near impossible to read the gauge properly. A good solution to this is to install a stilling well. If you already have one, all the better. You can put the gauge in there where you won’t find any turbulence. Then, you can get accurate measurements even if the turbulence is still relatively bad in the flume proper.

Dirty Gauge

Like everything else with flumes and weirs, your staff gauge will need to be maintained over time. As time passes, it’s likely that your gauge will accumulate some debris like biological growths, scum, and other kinds of dirt. If you want to keep getting accurate readings, you’ll need to make sure that all of this is regularly removed. To prevent the buildup from getting too bad, it’s generally best to clean the gauge every time you’re out at the site.

Staff Gauges from Tracom

If you want to avoid the most common problems with staff gauges, Tracom has got you covered. We can get you set up with a staff gauge that works well with your flume or weir box. Contact us today to get started!