When you measure using a flume or weir device, you must ensure that all of your measurements are accurate. Unfortunately, there are quite a few mistakes that can happen along the way, but the vast majority of them stem from the installation process. The equipment itself is rarely to blame for any errors you might encounter. It all comes down to installation. User error can be a problem, of course, but installation issues tend to be harder to fix. That’s why it’s so important that you avoid them to begin with. Changing how you take measurements is a whole lot easier than changing the way a flume is installed. Discover the most common mistakes with weir and flume installation, and learn how you can avoid them and take accurate measurements.

Fabrication Errors

When a device is created, it’s always best to have it specifically tailored to your unique flow channel conditions. That way, you can be sure that at least the potential for proper installation is there. Buying a weir or flume secondhand from a reseller always increases your risk of poor installation, which is why you should always opt for a manufacturer when you’re looking to get a device of your own. Weirs and flumes rely on specific dimensions to be able to measure flow rate properly. Any kind of variation can throw off your readings significantly, rendering your entire measurement efforts useless. The formulas used to determine flow rate depend on these dimensions to function properly, and when the figures are off, the math in these formulas can get out of hand fast. For weirs, one of the most common fabrication errors is having the elevation of the crest above the channel flow. The flow must be able to go over the crest in order for a weir to function properly. Additionally, the thickness of the weir crest can be off along with the notch angle. All of these factors must be specific for measurements to be accurate. Any deviation will lead to errors. When it comes to flumes, one of the most common errors is an incorrect throat width. Parshall flumes, the most researched type of flume, have a limit of +/- 2% when it comes to throat deviations. Smaller flumes like H flumes are even more vulnerable to this error because their throats are less than an inch in width. Opting for fiberglass flume is typically beneficial when it comes to avoiding errors like this, as the flume will be just as dimensionally sound as the mold is.

Failing to Set H a

The point of measurement, or H a , is where you must take your readings under normal conditions. Taking it at any other point is going to throw off your results. During the installation process, the proper point of measurement should be marked. If it’s not marked correctly, you’re going to have a problem. With both flumes and weirs, the point of measurement is always a singular location, so it’s essential that you get it right. H a is always going to be located upstream of the critical section of the weir or flume. Common errors regarding the point of measurement include mounting the measurement device, like a staff gauge, in the critical section rather than upstream of it. For a flume, that would be in the throat, while a weir would have it at the crest. Both locations here are wrong, so make sure your measurement device is installed in the correct spot.

Zeroing Incorrectly

Even if you get the correct point of measurement for your device, you still have to make sure your scale is zeroed properly. If it’s not zeroed properly, you’re going to have an inherent offset in all your measurements at a systemic level that can be tough to account for. Because discharge relationships for both weirs and flumes are nonlinear, your error is going to increase to a greater degree as the level of flow increases. A lot of flumes have the zero level on the floor of the flume, so that’s pretty easy to handle. If you have a style that doesn’t allow for that, however, you must be careful. Take an RBC or Palmer-Bowlus flume, for example. Their zero point is offset from the floor, being at the top of the ramp instead. If you’re using a weir, there are no scenarios in which the zero point is at the floor. Instead, it’s located about two to three times the maximum anticipated head from the floor of the flow channel. The problem with that is you can’t really measure the head to begin with if you don’t already have a reliable scale in place. That’s why the zero point needs to be pinpointed during the manufacturing and installation process.

Failure to Consider Measurement Logistics

The checklist for taking correct measurements can be a long one. Even if you’ve got the correct point of measurement and have everything zeroed correctly, you still need to be able to actually take accurate measurements. Quite a few installation factors can make this much more difficult than it needs to be, so make sure you give yourself room to take measurements before installation is complete. Imagine you’re using a staff gauge to take your measurements. The gauge is installed in line with the point of measurement, and it’s zeroed properly. Because of the angle, however, you can’t get a good reading on which tick marker the flow surface is at. If you can’t physically read the gauge, it won’t matter how well-placed it is in terms of accuracy. You always need to leave yourself an operator space to see what the reading is. There are a few factors to consider when placing your staff gauge. You’ll need to think about exactly how far away you’ll be when taking readings. If you’re more than a few feet away, you’ll need to make sure that the numbers on the gauge are legible from that distance. Opt for a bigger font size and more spaces between the ticks on the gauge. Additionally, you’ll need to make sure you’ve got the proper angle on the gauge. Reading from an odd angle may make you misinterpret what the gauge is showing.

Using a Device Unfit for the Flow

Every device, whether it’s a flume or a weir, has a functional range. This range represents what kind of flows the device can measure accurately. If a flow falls outside of this range in either direction, you can no longer rely on your device for accuracy. In fact, the error will be so severe that there aren’t any corrections you can make to account for it. You’re simply out of luck, which is why it’s so important to ensure that your device is capable of measuring the range of flow in your channel before installation. Consider both the size and type of weir or flume you opt for before installation. Each has a different range, and you’ll want one that can be best fit to your channel. For example, if your flow level is below 0.2 feet, you can essentially write off weirs entirely because that’s the minimum requirement for avoiding flow adhering to the downstream face. If your level is that low, some flumes may be more appropriate. If your flow is going to experience common changes in level, you may want to opt for a nested flume. Think of this as a dual-range flume or a flume within a flume that’s capable of handling a wider range of flows. You may also be able to raise sidewalls or implement wing walls in Parshall and Montana configurations with accurate discharge equations, but that’s not necessarily the case. It’s always best to talk to an expert when trying to design the perfect flume for your unique flow channel conditions.

Poor Installation Practices

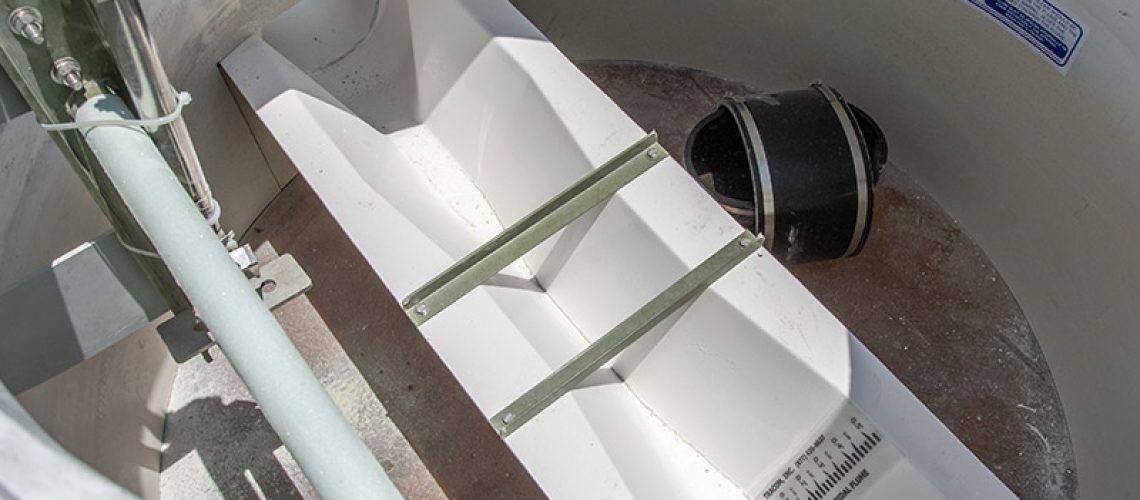

The physical act of installing a weir or a flume requires as much precision as the measurement process does. Without that kind of precision, your measurements won’t be accurate even if you did everything else correctly. With more serious errors, you could experience a bypass where the flow simply goes around your device, rendering the entire measurement process useless. When it comes to flumes, one of the most important aspects of installation is that the flume must be level. This includes both side-to-side leveling and front-to-back leveling. Any deviation from this will throw off your measurements significantly as the flow level cannot be properly measured when the dimensions of the flume are at an angle. Weirs have sizing requirements that cannot be understated. This is because they require a weir pool upstream of the weir itself. This is essential for conditioning the approaching flow correctly. Without a weir pool, a weir simply can’t do its job properly and offer accurate measurements. While it may seem tempting to underestimate the size of a weir pool to save space and effort, this can drastically alter your results to an extent that makes measurements fundamentally unreliable. Additionally, weirs require vertical weir plates, with any deviation from verticality throwing off how the flow travels over the crest.

Incorrect Approach

Conditions Both weirs and flumes require flows to be in a certain state before they can be accurately measured. Specifically, the flow must be tranquil and have a uniform velocity profile, meaning it can’t come at an angle, already be supercritical or be overly turbulent. If the flow is a bit too intense in any of these ways, you’re not going to be able to get accurate measurements. Making sure the approach conditions work for your flume or weir’s desired location is essential during the installation process. Of course, there are ways to alter the approach conditions to some degree if you’re experiencing relatively minor errors. You can install energy-absorbing manholes or stilling wells to help condition the flow, in addition to baffles. The best course, however, is to change the upstream hydraulics if possible to allow for a steady and uniform flow.

Failure to Maintain

Even if the installation process goes off without a hitch, all that hard work can be undone if you fail to provide your device with the proper maintenance. Weirs and flumes will degrade over time just like everything else, and proper maintenance can do a lot to extend that life span as much as possible. The biggest concern with weirs is removing sedimentation and debris in weir pools. The weir pool’s design will inevitably collect debris, and it’ll need to be cleared regularly to ensure that a buildup doesn’t interfere with the dimensions of the pool. Additionally, you’ll need to make sure that there isn’t any excessive crest rounding that could prevent the flow from passing over the crest properly. Clinging debris and growth can also be a problem around the crest, so that will need to be cleared out as well. When it comes to flumes, you’ll need to consider quite a few factors in addition to what style of flume you choose. Settlement both lateral and longitudinal can be corrected for in Parshall flumes, so you may need to alter your equations a bit. Still, it’s always best to correct the deficiencies rather than work around them. If you’re dealing with cold weather, you’ll need to check your flumes for frost heave that may have moved them out of place. If they’re set in earthen channels, it’s possible for the flow to bypass and undermine them as well over time.

Flume and Weir Installation With Tracom

If you’re looking to get the most out of your weir or flume installation, Tracom is happy to help. You can work with our team to design a device that works specifically with your unique open channel flow conditions. Using fiberglass construction, you can count on your flume being durable enough to last years and to be crafted to exact specifications. Contact us today to get started on your device!