One of the most common ways to measure flow rate in a fiberglass flume is to use a staff gauge. This simple device has measurements displayed on the side, and all you have to do is take the measurement where the surface of the water is. While that sounds simple enough, there are actually quite a few errors that are more common than you might think. Learn about the common errors with staff gauges, and discover what you should avoid.

Too Far for Viewing

A staff gauge can be easily read up close, but depending on the size of it, you may not be able to actually see the precise level the water surface is at if you’re too far away. When selecting the right staff gauge for your flume, you’ll need to consider how far away you’ll be when reading it. The bigger it is, the farther away you’ll be able to read it from. You can also increase readability at a distance by implementing contrasting colors with the increments and the background. Typically, dark-black increments on a bright-yellow background work best.

Odd Angles

If you find yourself reading the gauge at an angle, you may not be getting the accurate readings you need. In a lot of channeled systems, the flume is located below the viewing point, meaning any staff gauge will have to be read from above. This can cause problems where it’s hard to tell exactly where the surface level is. In instances where standing-level observations aren’t possible with space considerations in mind, you may not be able to use staff gauges at all.

Dirty Gauges

If the staff gauge isn’t properly maintained, you won’t be able to get accurate readings. While it happens faster to gauges located on flumes that are open to the elements, buildup, biological growth and dirt can accumulate on the gauge, blocking the displayed increments. Fortunately, this is very easy to fix provided you put the gauge in a place that’s reachable, allowing for quick maintenance and cleaning.

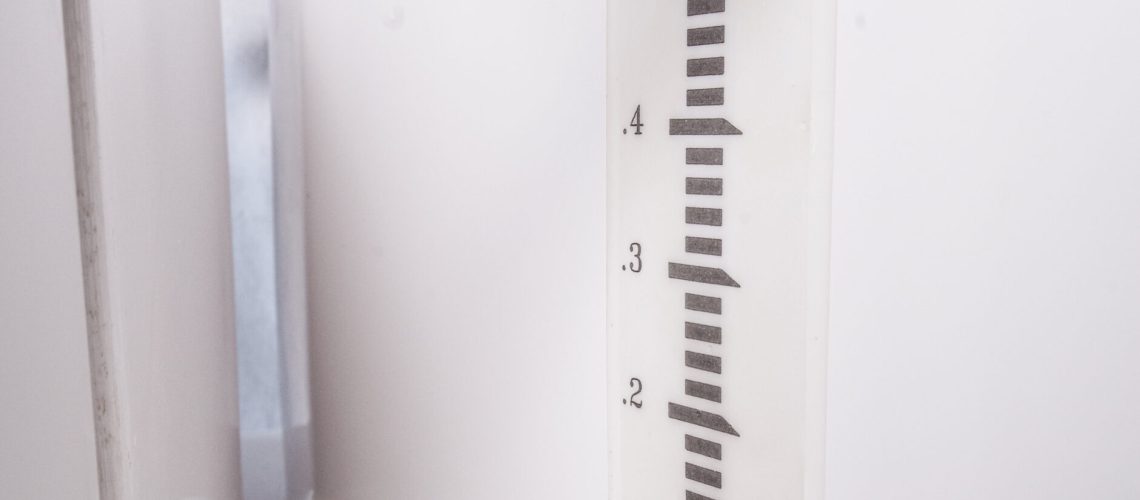

Too Many Gradations

It’s always helpful to be as exact as you can be in your measurements, but too many gradations on your staff gauge can cause problems. Typically, you won’t want to use any gradations finer than one-eighth of an inch. Anything more, and it doesn’t really add anything useful to the measurement. Plus, it can make reading the gauge harder even if you’re very close. In some cases in which the viewing point may be farther away, you won’t want gradations more than one-quarter of an inch.

Measuring With Turbulence

Turbulence can be an unavoidable part of your flow channel. When you have surface turbulence that’s not throwing off velocity but is past the point of easy readings, you’ll need to opt for a stilling well. When you add a stilling well, you can install your staff gauge there for easy readings that offer all the accuracy you need.

Staff Gauges From Tracom

Now that you know the common errors with staff gauges to avoid, you can get one of your own. At Tracom, we offer a variety of staff gauges for all sorts of flume styles and sizes. Contact us to find the perfect gauge for your flow channel.