Every operation requires accurate flow measurement, and this can be a tricky task to accomplish. It’s essential that your readings remain accurate to ensure the long-term success of your system and operation. Making even minor errors when measuring flow management can create a critical mess in your operation. Let’s take a look at a few of the common open channel flow application measurement errors that can create big problems, and learn how you can avoid them in your system.

Improper Installation

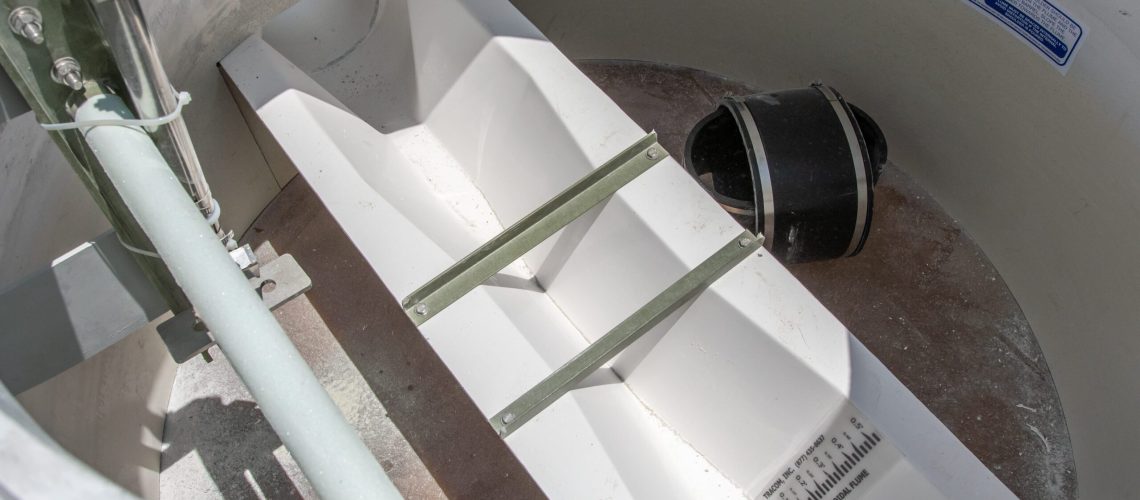

Improper installation is arguably the number one error that can mess up your flow operation. When your primary device isn’t installed right, it’s almost a guarantee of constant and consistent flow reading problems. You need to be sure that the device is sized correctly, that it’s properly leveled, and that it completely captures the flow.Choosing an Incorrect Point of Measurement

This one is the easiest flow measurement error to avoid, but strangely, it’s also a very common mistake. Your correct measurement point depends on what device you are using. Flumes, for example, need to be measured upstream of the throat. Weir devices need to be measured upstream of the crest. When you don’t choose the right measurement point, your readings will not be consistent or accurate, and your operations will be less successful.Wrong Device Size

Device size is just about everything when it comes to flow measurement. When the management device is the wrong size, it can make it all but impossible to get accurate readings at any point. This comes down to the primary device being able to handle the flow range of your system at both its highest and lowest points. If it can’t handle the flow rate properly, you won’t get good readings.Zeroing the Flow Meter

Zeroing the flow meter is also called calibration. When it’s not done right, the system will suffer an offset that will only increase as time goes on and levels increase. It can be complicated further by the fact that the zero level is offset from the floor. If you don’t know the proper zero level upfront, it can be hard to calibrate the meter.Improper Level Measurement

Any errors in determining the actual level of the flow can be just as problematic as improper zeroing. Novice users often make the critical mistake of taking a level reading from surface to floor. Unfortunately, in some devices this can over-report the level because of the ramp, sometimes by as much as double what it should be.Not Keeping up with Maintenance

Finally, too many people forego regular routine maintenance of the primary device. Any device needs to be maintained on occasion, keeping it clean, clear of debris, and ensuring there are no sediments or solid material clogging up the device. These can impede flow, and cause problems in measurement accuracy.Choose the Right Device with Tracom

The best way to ensure accurate measurements of the primary device is to have a high-quality device, whether a weir or a flume. Tracom offers a range of fiberglass products that can meet a flow management operation of any size. Get in touch with us for more information on choosing the right device, and to place your order today.