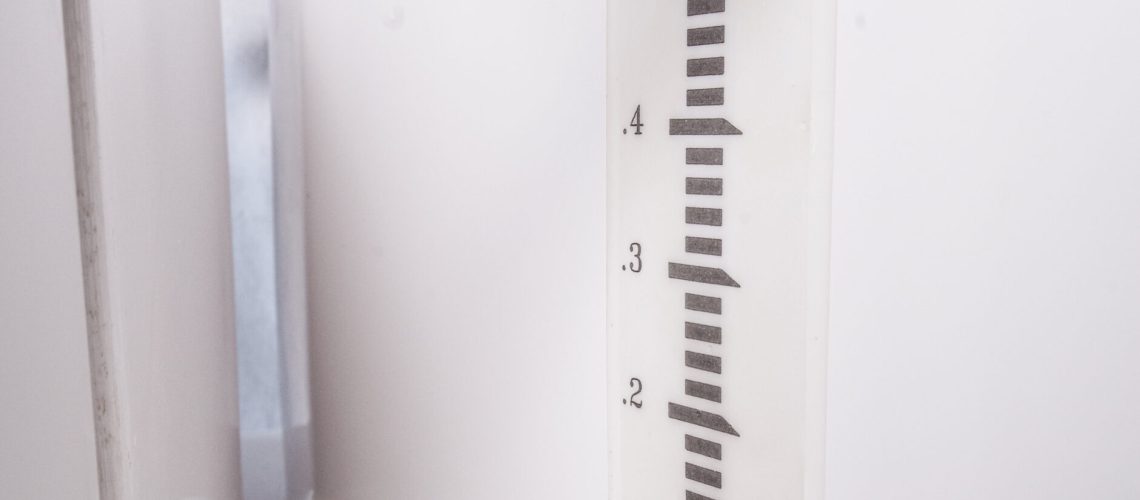

While there are plenty of ways to read flow rate measurements with a flume, one of the most basic is a staff gauge. A staff gauge doesn’t bother with ultrasonic pulses or anything too fancy, as it’s just a meter attached to the interior wall of the flume with measurements and notches on it. You see where the flow surface is on the meter, and you have your measurement for the equation. Unfortunately, it’s not always that simple. Learn about the most common problems of reading staff gauges and discover what to avoid when trying to take accurate flow rate measurements.

Font Size

In most cases, you can simply look at the staff gauge and read it to find your measurement, but this can sometimes be harder than it sounds. The font size of the staff gauge plays a huge role in readability, so you’ll want to make sure the font you opt for is suitable for the distance you’ll be reading at. Keep in mind that the readability of text tends to drop off quite quickly once you get to certain distances, so make sure to adjust accordingly when finding the right staff gauge.

There are a few tricks you can use to enhance the readability of the gauge if it’s going to be viewed from far away. The most obvious is to make the numerals larger. Another effective strategy is to increase the color contrast between the gauge background and the markers. For example, having standard black numerals on a bright yellow background is fairly common due to the contrast.

Reading Angle

The best angle to read a staff gauge would be from slightly above the surface of the flow to clearly see where the flow is hitting the gauge. Unfortunately, that kind of angle isn’t always available. In some cases, the reader will find themselves far above the actual gauge. While this can still work, it makes turbulence far more difficult to deal with. Alternatively, they could read the gauge from under the surface if that’s where the best viewing position is, but this can be even harder to determine.

Turbulence

Turbulence is always a problem even if you’re not reading the gauge from an odd angle. If turbulence is a significant problem, you may have to implement flow conditioners like a stilling well. In those cases, it’s typically best for the staff gauge itself to be implemented within the stilling well. The level in the stilling well won’t be dealing with turbulent conditions and can reflect an accurate reading. Just keep in mind that stilling well lag can throw off the accuracy.

Cleanliness

Keeping the flume free of debris and sediment is normal for routine maintenance. Anything that changes the dimensions of the flume, such as buildup, is going to be inherently problematic. The staff gauge itself can suffer from debris and sediment as well. You’ll want to make sure you’re cleaning it regularly to ensure all the numerals and notches on the gauge are legible.

Staff Gauges From Tracom

With the common problems reading staff gauges in mind, you’re ready to make the most of this handy measurement device. Tracom offers many staff gauge types & styles. Whether you’re looking for a standard new one or something customized for a flume with an angled wall. Contact us today to get started!