When you’re looking to measure flow rate with a flume or a weir box, there are quite a few factors to keep in mind. A variety of different functions need to occur simultaneously, and all your efforts must be right or you’ll wind up with inaccurate measurements. Here are some of the most common mistakes with flow rate measurements that you should watch out for.

Fabrication Errors

The potential for fabrication errors is why you want to choose your flume manufacturer very carefully. Any variation from the proper dimensions will throw off your readings and render all of your efforts functionally useless. If you have a flume, for example, a significant deviation in the throat width, or the portion where the flume is the most narrow, will throw off your measurements. The degree of error can vary depending on flume design, but the popular Parshall flume, for example, can only withstand about a +/- 2% deviation.

There are ways to ensure that your flume or weir is fabricated properly. Picking a reliable manufacturer is always a necessity, of course, but you may also want to opt for fiberglass as a construction material. Thanks to the way fiberglass is made and the nature of the material itself, you can decrease the likelihood of any fabrication errors to a greater degree than any other material can offer.

Measurement Errors

The act of measuring a flow rate isn’t foolproof. In fact, the only way you can get proper measurements is by measuring the right spot. Unfortunately, many people use the wrong spot for measurement. This is likely due to the function of a flume or weir. To manage flows, flumes and weirs direct a subcritical flow to a supercritical flow while passing through a critical state. Achieving criticality is essential.

Given the emphasis on criticality when one learns how a flume functions, many assume that’s the point of measurement. With flumes and weirs, however, that is not the case. The point of measurement is always located upstream of the point of criticality rather than right at it. That means the point of measurement needs to be before the throat of a flume or before the crest of a weir.

Installation Errors

The installation process is a key factor in how any flume or weir will function, so you have to get it right for accurate measurements. When you’re installing a flume, for example, the most important factor is that it is level. Not only must it be level from front to back, but it must also be level from side to side.

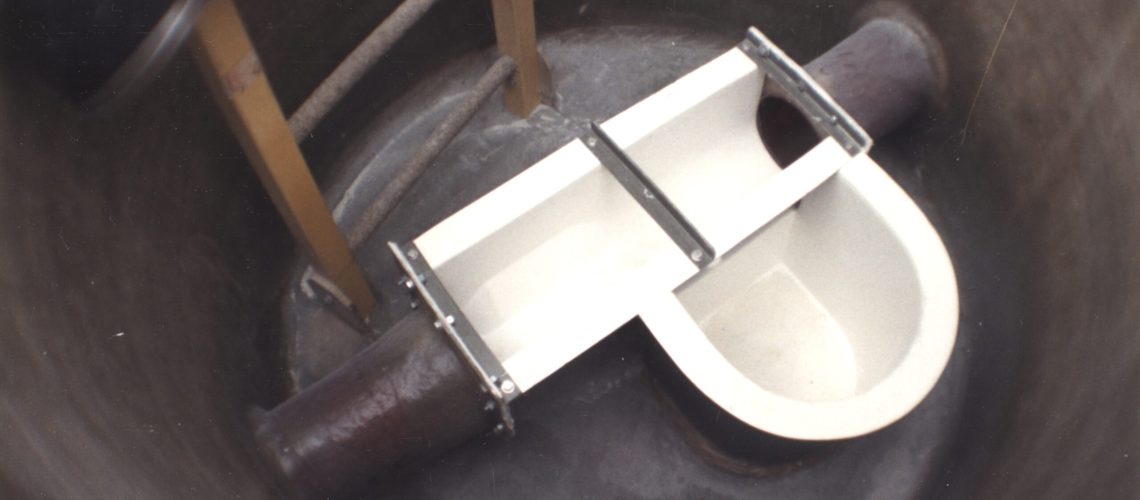

Weirs work a bit differently from flumes, and they’re much more difficult to install. With a weir, you’ll need to have a weir pool that can properly condition the approaching flow, allowing for proper measurements. If the weir pool is too small, the approach velocity may already be supercritical, leading to altered measurements. Plus, the orientation and thickness of weir plates can throw off measurements as well.

Master Flow Measurement With Tracom

If you’re looking to avoid common mistakes with flow rate measurements, Tracom is happy to help. Our experts can craft a flume or weir to exact specifications and ensure that you’re taking the right measurements after a proper installation. Contact us today to learn more about our water and wastewater applications.